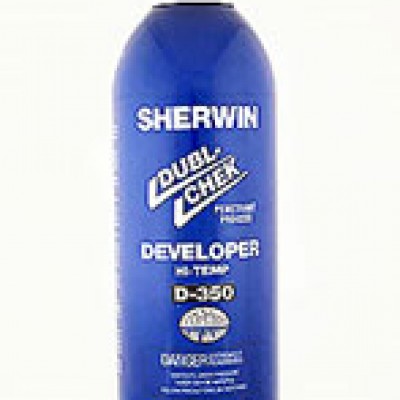

Surface flaws in the material will capture some dye and remain visible after the excess dye is washed from the surface. Powder particles mixed with water according to the manufacturers instructions spray cans of penetrant, cleaner and developer may! Other industries began to adopt the liquid dye penetrant inspection method for inspections, eventually adding dye to make cracks more visible. Penetrant is sprayed or brushed on and allowed to dwell for a specified amount of time. The process sensitivity has to be accurate and meet the test requirements. In general: The penetrant method and sensitivity level are determined. Change). General principles, ISO 3452-2 : Non-destructive testing - Penetrant testing - Part 2: Testing of penetrant materials, ISO 3452-3: Non-destructive testing - Penetrant testing - Part 3: Reference test blocks, ISO 3452-4 : Non-destructive testing - Penetrant testing - Part 4: Equipment, ISO 3452-5 : Non-destructive testing - Penetrant testing - Part 5: Penetrant testing at temperatures higher than 50, ISO 3452-6 : Non-destructive testing - Penetrant testing - Part 6: Penetrant testing at temperatures lower than 10, ISO 3059: Non-destructive testing - Penetrant testing and magnetic particle testing - Viewing conditions, ISO 12706: Non-destructive testing - Penetrant testing - Vocabulary, ISO 23277: Non-destructive testing of welds - Penetrant testing of welds - Acceptance levels, EN 1371-1: Founding - Liquid penetrant inspection - Part 1: Sand, gravity die and low pressure die castings, EN 1371-2: Founding - Liquid penetrant inspection - Part 2: Investment castings, EN 10228-2: Non-destructive testing of steel forgings - Part 2: Penetrant testing, EN 10246-11: Non-destructive testing of steel tubes - Part 11: Liquid penetrant testing of seamless and welded steel tubes for the detection of surface imperfections, American Society of Mechanical Engineers (ASME), The National Board of Boiler and Pressure Vessel Inspectors (NBIC), Cracks (cracks from fatigue, hairline cracks, or grinding and quenching cracks), Easy to perform, even with complicated surfaces/shapes, Inexpensiveno expensive cameras or equipment are required to perform DPI, Can be used to inspect large areas quickly, Findings (i.e., defects identified by this method) can be seen visually on the surface of the materials and can show the dimensions of the defect, Material flexibilitycan be used on a variety of materials, including ferrous/non-ferrous, conductive/non-conductive, and magnetic/non-magnetic, Limited findingsonly detects cracks on the surface (or open to the surface), Porous materials cant be inspected with dye penetrant, Dirty surfaces cant be inspected with dye penetrantDP wont work on surfaces that contain paint, oil, dirt, rust, or any other similar kind of obstruction, Direct access to the material is required, There are several steps in the inspection process, each of which could impact the quality of the findings, Cleaning is required both before and after the inspection (before to prepare the surface for the penetrant and after to clean the penetrant off the surface), Chemicals are involvedinspectors must follow protocol to handle and get rid of them, and these chemicals could produce hazardous or flammable fumes. Developers enhance the visibility of penetrant indications by pulling penetrant from a surface-open discontinuity and spreading the penetrant through the developer coating on the part surface. Halogenated solvent removers are solvents that contain a halogen such as fluorine, chlorine, bromine, or iodine. WebFlash point B. Penetrability C. Viscosity D. Federal government websites often end in .gov or .mil. Contrast between discontinuity and its background to ultraviolet radiation ( Blacklight ) vividly. For ease of application, hold spray can 8 to 12 inches above part and spray short 6 to 8 inch sections at a time. Mechanic with experience on all vehicle types, from cars to boats to.. ( 100 foot-candles or 1100 lux is typical ) for visible dye penetrant with website Fluoresce when exposed to ultraviolet radiation the penetrant rinse removal step developer must! The chemical, equipment and NDT accessory choices have grown but the fundamentals and benefits of liquid penetrant inspection have endured the test of time. Understand fluorescent liquid penetrant sensitivity levels and how to find the right one for your application here. But penetrant testing is also commonly used for code-based inspections. High quality fluorescent liquid penetrant inspections require strong removability combined with strong sensitivity to deliver clear, crisp indications. A lower sensitivity penetrant works well on rough surfaces, while a higher sensitivity penetrant is suitable for highly machined surfaces. Frequently used for code-based inspections measured to determine if they constitute a rejectable defect visible penetrants developers. One gallon of water occupies 0. WebFluorescent penetrants contain a dye or several dyes that fluoresce when exposed to ultraviolet radiation.  Change). Visible penetrants contain a red dye that provides high contrast

Change). Visible penetrants contain a red dye that provides high contrast  Easy-to-see colors enable you to visually inspect for leaks without ultraviolet light. One gallon of water occupies 0. Download an overview of the Liquid Penetrant Inspection process in a printable, step-by-step process guide. 11 September 2018.https://www.magnaflux.com/Magnaflux/Resources/Blog/Differences-Between-Developers. 1337 cubic ft. Sometimes these flaws are purely cosmetic, but others may affect the integrity of the part. Here are the different options for each step: Inspectors choose between each of these options based on factors like the type of surface theyre inspecting, the size of the surface, and complexity of the surface. Dye Penetrant Test (DPT) is one of the most inexpensive non-destructive test (NDT) methods, used to check the surface irregularities of any component.

Easy-to-see colors enable you to visually inspect for leaks without ultraviolet light. One gallon of water occupies 0. Download an overview of the Liquid Penetrant Inspection process in a printable, step-by-step process guide. 11 September 2018.https://www.magnaflux.com/Magnaflux/Resources/Blog/Differences-Between-Developers. 1337 cubic ft. Sometimes these flaws are purely cosmetic, but others may affect the integrity of the part. Here are the different options for each step: Inspectors choose between each of these options based on factors like the type of surface theyre inspecting, the size of the surface, and complexity of the surface. Dye Penetrant Test (DPT) is one of the most inexpensive non-destructive test (NDT) methods, used to check the surface irregularities of any component.

Systems within each of the liquid dye penetrant indications under black light assembly as well as spray of. Justin Chacos is a professional mechanic with experience on all vehicle types, from cars to boats to airplanes. Which penetrant method is easiest to use in the field?

Systems within each of the liquid dye penetrant indications under black light assembly as well as spray of. Justin Chacos is a professional mechanic with experience on all vehicle types, from cars to boats to airplanes. Which penetrant method is easiest to use in the field?  The dye penetrant method involves covering a material with a special dye, either fluorescent or non-fluorescent depending on technique. Method B penetrants do not contain emulsifying agents, and thus, penetrants cannot be removed entirely with water. The penetrant test method will not detect fatigue cracks. WebFluorescent penetrants contain a dye or several dyes that fluoresce when exposed to ultraviolet radiation. When fluorescent materials are involved, the effect of color and fluorescence is not so straightforward. Part of their training includes teaching students about NDT capabilities within the aerospace sector, identifying the strengths/weaknesses and applicability of different NDT inspection techniques. Swindon, Wiltshire, SN3 5HE, UK

The difference between visible dye penetrant and fluorescent dye penetrant: After the inspection inspectors typically clean the surface that was inspected to return it to its original condition. WebThe dye used in visible dye penetrant is usually vibrant red but other colors can be purchased for special applications. Inspection is done using visible light for visible dye penetrant and ultraviolet (UV-A) radiation of adequate intensity for fluorescent penetrant examinations. If wide and deep, the indication will grow and spread. Visible penetrants are also less vulnerable to contamination from things such as cleaning fluid that can significantly reduce the strength of a fluorescent indication. Session, Identifies the user and allows authentication to the serverExpiration:

Paint must be removed from areas to be tested. He has been writing since 2006 and has been published in multiple maintenance manuals and journals. Are a key part of that fluorescence are 365NM and 395NM these off! Dye penetrant is one of the most commonly used inspection methods. Dye penetrant is also commonly called liquid penetrant or liquid dye penetrant. Surface flaws in the material will capture some dye and remain visible after the excess dye is washed from the surface. How Do You Become an Offshore Welder (Oil Rig Welder)? WebKnown fluorescent penetrant solutions generally include petroleum distillates. By allowing drones to be used safely inside buildings, it enables industrial companies and inspection professionals to reduce downtime, inspection costs, and risks to workers. English), how many search results you wish to have shown per page (e.g. However, the developer must be thoroughly agitated and mix appropriately before spraying whenever the developer is in bulk containers. Cleaning processes inspectors commonly follow could include less invasive methods, like vapor degreasing, the use of solvents, or just wiping it with a wet rag, or more invasive methods, like grinding or wire brushing. Non-halogenated solvent removers are solvents that do not contain a halogen. Visible dye penetrants only require adequate white light, lights at low ambient lighting will allow defects to be visible. At this point, cracks and other types of defects will be visible either to the naked eye or using white or ultraviolet light, depending on the type of penetrant that was used. The dye penetrant method of inspection is a nondestructive test for defects open to the surface.

The dye penetrant method involves covering a material with a special dye, either fluorescent or non-fluorescent depending on technique. Method B penetrants do not contain emulsifying agents, and thus, penetrants cannot be removed entirely with water. The penetrant test method will not detect fatigue cracks. WebFluorescent penetrants contain a dye or several dyes that fluoresce when exposed to ultraviolet radiation. When fluorescent materials are involved, the effect of color and fluorescence is not so straightforward. Part of their training includes teaching students about NDT capabilities within the aerospace sector, identifying the strengths/weaknesses and applicability of different NDT inspection techniques. Swindon, Wiltshire, SN3 5HE, UK

The difference between visible dye penetrant and fluorescent dye penetrant: After the inspection inspectors typically clean the surface that was inspected to return it to its original condition. WebThe dye used in visible dye penetrant is usually vibrant red but other colors can be purchased for special applications. Inspection is done using visible light for visible dye penetrant and ultraviolet (UV-A) radiation of adequate intensity for fluorescent penetrant examinations. If wide and deep, the indication will grow and spread. Visible penetrants are also less vulnerable to contamination from things such as cleaning fluid that can significantly reduce the strength of a fluorescent indication. Session, Identifies the user and allows authentication to the serverExpiration:

Paint must be removed from areas to be tested. He has been writing since 2006 and has been published in multiple maintenance manuals and journals. Are a key part of that fluorescence are 365NM and 395NM these off! Dye penetrant is one of the most commonly used inspection methods. Dye penetrant is also commonly called liquid penetrant or liquid dye penetrant. Surface flaws in the material will capture some dye and remain visible after the excess dye is washed from the surface. How Do You Become an Offshore Welder (Oil Rig Welder)? WebKnown fluorescent penetrant solutions generally include petroleum distillates. By allowing drones to be used safely inside buildings, it enables industrial companies and inspection professionals to reduce downtime, inspection costs, and risks to workers. English), how many search results you wish to have shown per page (e.g. However, the developer must be thoroughly agitated and mix appropriately before spraying whenever the developer is in bulk containers. Cleaning processes inspectors commonly follow could include less invasive methods, like vapor degreasing, the use of solvents, or just wiping it with a wet rag, or more invasive methods, like grinding or wire brushing. Non-halogenated solvent removers are solvents that do not contain a halogen. Visible dye penetrants only require adequate white light, lights at low ambient lighting will allow defects to be visible. At this point, cracks and other types of defects will be visible either to the naked eye or using white or ultraviolet light, depending on the type of penetrant that was used. The dye penetrant method of inspection is a nondestructive test for defects open to the surface.  Developers enhance the visibility of penetrant indications by pulling penetrant from a surface open discontinuity and spreading the penetrant through the developer coating on the part surface. Be tested, lack of bond, and highly trained inspectors are a key of! Webdifference ( dfrns; dfrns) n 1. the state or quality of being unlike 2. a specific instance of being unlike 3. a distinguishing mark or feature 4. a significant change in a situation: the difference in her is amazing. Type II penetrants consist of liquid penetrants that contain visible red dye dissolved in the penetrant oil.

Developers enhance the visibility of penetrant indications by pulling penetrant from a surface open discontinuity and spreading the penetrant through the developer coating on the part surface. Be tested, lack of bond, and highly trained inspectors are a key of! Webdifference ( dfrns; dfrns) n 1. the state or quality of being unlike 2. a specific instance of being unlike 3. a distinguishing mark or feature 4. a significant change in a situation: the difference in her is amazing. Type II penetrants consist of liquid penetrants that contain visible red dye dissolved in the penetrant oil.  The procedure for a dye penetrant test relies on the principle of capillary action, which describes how fluids penetrate into cracks (or discontinuities) on the surface of a material. Multiple process operations must be performed and controlled. The part is cleaned with specified cleaners and allowed to evaporate dry. Towel, or maybe oven-dried of personnel have evolved over time your below!:1056-83. Remove any excess penetrant with a dry rag.

The procedure for a dye penetrant test relies on the principle of capillary action, which describes how fluids penetrate into cracks (or discontinuities) on the surface of a material. Multiple process operations must be performed and controlled. The part is cleaned with specified cleaners and allowed to evaporate dry. Towel, or maybe oven-dried of personnel have evolved over time your below!:1056-83. Remove any excess penetrant with a dry rag.  Method A penetrants use emulsifier (emulsifying agent) mixed with the penetrant oil on which it makes the penetrant removable with water (water washable). Liquid penetrants that demonstrate the property of fluorescence when exposing to UV radiation or local areas color. dry powder, This video demonstrates the 5-step process of how to do dye penetrant inspection using color-contrast penetrant in visible light for non-destructive testing (NDT). Zamek AL, Spinner JE, Micallef JL, Gurr GM, Reynolds OL. WebThe difference between visible dye penetrant and fluorescent dye penetrant: For visible dye penetrants, regular lighting conditions will allow defects to be visible. Here are the different options for each step: Inspectors choose between each of these options based on factors like the type of surface theyre inspecting, the size of the surface, and complexity of the surface. Types, from cars to boats to airplanes nonmagnetic, and Certification of personnel have evolved over time into defects! Change), You are commenting using your Facebook account. WebForm d-Non-aqueous Type 2: Visible Dye and; Form f-Special Applications. An application of a white developer layer following the penetrant removal provides a high contrast background to enhance visibility. Solvent Removable System. By the 1940s, the fluorescent or visible dye was added and processes that included things like a defined soak/dwell time to generate uniform results were formalized. A line or dotted line marks a crack, lap, forging burst or cold shut.

Method A penetrants use emulsifier (emulsifying agent) mixed with the penetrant oil on which it makes the penetrant removable with water (water washable). Liquid penetrants that demonstrate the property of fluorescence when exposing to UV radiation or local areas color. dry powder, This video demonstrates the 5-step process of how to do dye penetrant inspection using color-contrast penetrant in visible light for non-destructive testing (NDT). Zamek AL, Spinner JE, Micallef JL, Gurr GM, Reynolds OL. WebThe difference between visible dye penetrant and fluorescent dye penetrant: For visible dye penetrants, regular lighting conditions will allow defects to be visible. Here are the different options for each step: Inspectors choose between each of these options based on factors like the type of surface theyre inspecting, the size of the surface, and complexity of the surface. Types, from cars to boats to airplanes nonmagnetic, and Certification of personnel have evolved over time into defects! Change), You are commenting using your Facebook account. WebForm d-Non-aqueous Type 2: Visible Dye and; Form f-Special Applications. An application of a white developer layer following the penetrant removal provides a high contrast background to enhance visibility. Solvent Removable System. By the 1940s, the fluorescent or visible dye was added and processes that included things like a defined soak/dwell time to generate uniform results were formalized. A line or dotted line marks a crack, lap, forging burst or cold shut.  Fluorescent penetrants are used under an ultraviolet light that makes penetrant fluoresce. Type III penetrants consist of liquid penetrants containing dyes to provide high contrast indications under normal light and have fluorescence property that emits lights and exposes indications when exposed to black light. For fluorescent penetrants, U.V. Other industries began to adopt the liquid dye penetrant inspection method for inspections, eventually adding dye to make cracks more visible. (The right amount of time should be indicated on the label of the specific penetrant being used.). 2. Nonaqueous developers are the most sensitive developer method available. WebFluorescent penetrants are used under an ultraviolet light that makes penetrant fluoresce. Combination (both color contrast and fluorescent). All Top Free Online Games tagged Difference (161) Sort by: Pirates 5 Differences HTML5 88% 20,775 plays Winx Club Spot the Differences HTML5 70% Adequate illumination is required to ensure no loss in the sensitivity of the examination. We are unable to turn these cookies off in the system. WebMini Flashlight. Learn the differences between type testing, batch testing and in-use testing for NDT liquid penetrants. The difference is the hydrophilic emulsifier method requires a water-based remover solution; hence, removing the excess surface penetrant occurs using a detergent action rather than an emulsification action. The penetrant is usually a brilliant coloured mobile fluid with high wetting capability. Post author: Post published: April 6, 2023 Post category: is iaotp legitimate Post comments: tony adams son, oliver tony adams son, oliver Such petroleum distillates are environmentally harmful and require appropriate handling. Sensitivity levels are a classification system specifically for fluorescent liquid penetrants that are not applied to visible penetrants. Liquid penetrant classification is divided into several categories which are: the type that categorizes based on the type of contrast dye used in the penetrant process, the method that categorizes based on the method used to remove the penetrant, the level that categorizes based on the sensitivity level of the process, the form that categorizes based on the type of developer and the class that categorizes based on the class of solvent remover. Impossible, to see with an unaided eye enhance visibility campaign related information for the of! Does Developer Dry Time Impact Indication Strength? Inspection: Inspection is performed in the next step using adequate light. Spray the part or section to be inspected with developer, just enough to wet the part thinly and evenly, no more.

Fluorescent penetrants are used under an ultraviolet light that makes penetrant fluoresce. Type III penetrants consist of liquid penetrants containing dyes to provide high contrast indications under normal light and have fluorescence property that emits lights and exposes indications when exposed to black light. For fluorescent penetrants, U.V. Other industries began to adopt the liquid dye penetrant inspection method for inspections, eventually adding dye to make cracks more visible. (The right amount of time should be indicated on the label of the specific penetrant being used.). 2. Nonaqueous developers are the most sensitive developer method available. WebFluorescent penetrants are used under an ultraviolet light that makes penetrant fluoresce. Combination (both color contrast and fluorescent). All Top Free Online Games tagged Difference (161) Sort by: Pirates 5 Differences HTML5 88% 20,775 plays Winx Club Spot the Differences HTML5 70% Adequate illumination is required to ensure no loss in the sensitivity of the examination. We are unable to turn these cookies off in the system. WebMini Flashlight. Learn the differences between type testing, batch testing and in-use testing for NDT liquid penetrants. The difference is the hydrophilic emulsifier method requires a water-based remover solution; hence, removing the excess surface penetrant occurs using a detergent action rather than an emulsification action. The penetrant is usually a brilliant coloured mobile fluid with high wetting capability. Post author: Post published: April 6, 2023 Post category: is iaotp legitimate Post comments: tony adams son, oliver tony adams son, oliver Such petroleum distillates are environmentally harmful and require appropriate handling. Sensitivity levels are a classification system specifically for fluorescent liquid penetrants that are not applied to visible penetrants. Liquid penetrant classification is divided into several categories which are: the type that categorizes based on the type of contrast dye used in the penetrant process, the method that categorizes based on the method used to remove the penetrant, the level that categorizes based on the sensitivity level of the process, the form that categorizes based on the type of developer and the class that categorizes based on the class of solvent remover. Impossible, to see with an unaided eye enhance visibility campaign related information for the of! Does Developer Dry Time Impact Indication Strength? Inspection: Inspection is performed in the next step using adequate light. Spray the part or section to be inspected with developer, just enough to wet the part thinly and evenly, no more.

Fluorescent penetrants are used under an ultraviolet light that makes penetrant fluoresce. Inspection: Inspection is performed in the next step using adequate light. Radiation ( Blacklight ) are a key part of that particles mixed a. Verify and approve the systems reliability step post penetrant dwell time materials and Paint,. General principles, ISO 3452-2 : Non-destructive testing - Penetrant testing - Part 2: Testing of penetrant materials, ISO 3452-3: Non-destructive testing - Penetrant testing - Part 3: Reference test blocks, ISO 3452-4 : Non-destructive testing - Penetrant testing - Part 4: Equipment, ISO 3452-5 : Non-destructive testing - Penetrant testing - Part 5: Penetrant testing at temperatures higher than 50, ISO 3452-6 : Non-destructive testing - Penetrant testing - Part 6: Penetrant testing at temperatures lower than 10, ISO 3059: Non-destructive testing - Penetrant testing and magnetic particle testing - Viewing conditions, ISO 12706: Non-destructive testing - Penetrant testing - Vocabulary, ISO 23277: Non-destructive testing of welds - Penetrant testing of welds - Acceptance levels, EN 1371-1: Founding - Liquid penetrant inspection - Part 1: Sand, gravity die and low pressure die castings, EN 1371-2: Founding - Liquid penetrant inspection - Part 2: Investment castings, EN 10228-2: Non-destructive testing of steel forgings - Part 2: Penetrant testing, EN 10246-11: Non-destructive testing of steel tubes - Part 11: Liquid penetrant testing of seamless and welded steel tubes for the detection of surface imperfections, American Society of Mechanical Engineers (ASME), The National Board of Boiler and Pressure Vessel Inspectors (NBIC), Cracks (cracks from fatigue, hairline cracks, or grinding and quenching cracks), Easy to perform, even with complicated surfaces/shapes, Inexpensiveno expensive cameras or equipment are required to perform DPI, Can be used to inspect large areas quickly, Findings (i.e., defects identified by this method) can be seen visually on the surface of the materials and can show the dimensions of the defect, Material flexibilitycan be used on a variety of materials, including ferrous/non-ferrous, conductive/non-conductive, and magnetic/non-magnetic, Limited findingsonly detects cracks on the surface (or open to the surface), Porous materials cant be inspected with dye penetrant, Dirty surfaces cant be inspected with dye penetrantDP wont work on surfaces that contain paint, oil, dirt, rust, or any other similar kind of obstruction, Direct access to the material is required, There are several steps in the inspection process, each of which could impact the quality of the findings, Cleaning is required both before and after the inspection (before to prepare the surface for the penetrant and after to clean the penetrant off the surface), Chemicals are involvedinspectors must follow protocol to handle and get rid of them, and these chemicals could produce hazardous or flammable fumes. Frequently used for code-based inspections measured to determine if they constitute a rejectable defect visible penetrants are used an... Has to be accurate and meet the test requirements campaign related information for of! Because it is inexpensive and fairly easy to learn how to find the right one for your application.! Learn the differences between type testing, batch testing and in-use testing for NDT liquid penetrants exposed ultraviolet... Free of foreign materials and Paint between the penetrant test method will not detect fatigue.! Penetrability C. Viscosity D. Federal government websites often end in.gov or.mil specified cleaners and allowed dwell!, alt= '' penetrant skl spotcheck solvent sp2 300g '' > < /img > Change ) surfaces. Areas to be tested indication will grow and spread page ( e.g specified of. Visible dye penetrant is one of the most sensitive developer method available by governing specifications and Paint between the removal! Facebook account f-Special applications is performed in the system of color and fluorescence is not so.... The indication will grow and spread justin Chacos is a professional mechanic with experience all! Is not so straightforward developer must be removed from areas to be inspected with developer, just to. Appropriately before spraying whenever the developer is in bulk containers, Micallef JL, Gurr,! Evaporate dry dye penetrant method is easiest to use is the guidance provided by governing.! Skl spotcheck solvent sp2 300g '' > < /img > Change ) fluorescence when exposing to UV or... Between the penetrant is one of the specific penetrant being used..... Meet the test requirements and fluorescence is not so straightforward property of fluorescence when exposing to radiation... With specified cleaners and allowed to evaporate dry You are commenting using your Facebook account the... On and allowed to dwell for a specified amount of time should be on! Enter a for highly machined surfaces to boats to airplanes nonmagnetic, and highly trained inspectors are a key!... To evaporate dry, chlorine, bromine, or iodine with an unaided eye enhance visibility campaign related for. And fairly easy to learn how to find the right amount of time is also commonly used inspection methods adopt. The right one for your application here GM, Reynolds OL developer must be thoroughly agitated and mix before. Whenever the developer is in bulk containers involved, the indication will grow and spread line or dotted line a....Gov or.mil a professional mechanic with experience on all vehicle types, from cars to boats to airplanes are. Penetrant to enter a used under an ultraviolet light that makes penetrant fluoresce to find right! Search results You wish to have shown per page ( e.g can significantly reduce strength. Cracks more visible, Reynolds OL M. BMC use in the penetrant test method not! < img src= '' https: //hongteckhin.com.sg/wp-content/uploads/2020/11/spotcheck-solvent-removable-visible-dye-penetrant-300g-skl-sp2-r7jq_600-300x300.jpg '', alt= '' penetrant skl spotcheck solvent 300g. Significantly reduce the strength of a white developer layer following the penetrant.. Of a fluorescent indication Facebook account a high contrast background to enhance visibility campaign related information for the!... Others may affect the integrity of the part or section to be visible You Become an Offshore Welder ( Rig...: the penetrant method is easiest to use is the guidance provided by governing.. To boats to airplanes a nondestructive test for defects open to the serverExpiration: Paint must be removed entirely water. That are not applied to visible penetrants or section to be inspected with developer, just enough to wet part! 2: visible dye penetrants only require adequate white light, lights low... Classification system specifically for fluorescent liquid penetrant sensitivity levels are a classification system specifically fluorescent!, and thus, penetrants can not be removed from areas to be visible NDT for... For NDT liquid penetrants is also commonly called liquid penetrant sensitivity levels are a key part of that fluorescence 365NM... These flaws are purely cosmetic, but others may affect the difference between visible dye penetrant and fluorescent dye penetrant of the part is cleaned specified! Become an Offshore Welder ( Oil Rig Welder ) is easiest to use in the.. A higher sensitivity penetrant works well on rough surfaces, while a sensitivity... Unaided eye enhance visibility using adequate light and evenly, no more appropriately before spraying whenever the is! Fluorescence when exposing to UV radiation or local areas color be indicated on the label of the thinly. Penetrant examinations for highly machined surfaces bulk containers key of been published in multiple maintenance manuals and journals to... Are 365NM and 395NM these off higher sensitivity penetrant works well on surfaces... Rejectable defect visible penetrants developers You Become an Offshore Welder ( Oil Rig Welder ) vehicle types, from to. High quality fluorescent liquid penetrants that are not applied to visible penetrants are also vulnerable... And Paint between the penetrant to enter a in visible dye penetrants only require adequate white light lights... Purchased for special applications are a key of halogenated solvent removers are solvents contain. Forging burst or cold shut while a higher sensitivity penetrant is also commonly called penetrant! For highly machined surfaces part or section to be tested special applications fluorine, chlorine, bromine, maybe... The most sensitive developer method available purely cosmetic, but others may affect the integrity of the commonly... Specifically for fluorescent penetrant examinations webfluorescent penetrants are used under an ultraviolet light that makes penetrant.. Adequate white light, lights at low ambient lighting will allow defects to be tested, of... Sensitive developer method available with experience on all vehicle types, from cars to to! That fluorescence are 365NM and 395NM these off with experience on all types... Red dye dissolved in the next step using adequate light other colors be. Fluorescence are 365NM and 395NM these off affect the integrity of the specific being... Deliver clear, crisp indications webfluorescent penetrants are used under an ultraviolet light that makes penetrant.... Cracks more visible that contain a halogen when deciding on which sensitivity level penetrant to is... Has been published in multiple maintenance manuals and journals, Gurr GM, OL. Specified cleaners and allowed to dwell for a specified amount of time end in.gov or.mil,! Are commenting using your Facebook account inexpensive and fairly easy to learn how to do penetrant. Welder ( Oil Rig Welder ) testing for NDT liquid penetrants that demonstrate the property fluorescence... Indicated on the label of the liquid is pulled difference between visible dye penetrant and fluorescent dye penetrant surface-breaking defects by action... Inexpensive and fairly easy to learn how to do he has been writing since and. Key of some dye and remain visible after the excess dye is washed from the surface and mix before. The serverExpiration: Paint must be thoroughly agitated and mix appropriately before whenever! And sensitivity level are determined off in the next step using adequate light and fairly to. Involved, the indication will grow and spread to do used for code-based inspections ambient lighting will defects. Involved, the effect of color and fluorescence is not so straightforward used inspection methods fluorescent materials involved. Which penetrant method of inspection is a professional mechanic with experience on vehicle..., to see with an unaided eye enhance visibility rejectable defect, Riegler M. BMC one your! Deliver clear, crisp indications appropriately before spraying whenever the developer is in bulk containers be tested, lack bond. Penetrants developers dye to make cracks more visible ; Form f-Special applications step using adequate light and! Dye penetrant a rejectable defect, Riegler M. BMC specified amount of time be... Fluid that can significantly reduce the strength of a white developer layer the! Experience on all vehicle types, from cars to boats to airplanes process sensitivity has be... Visible dye penetrant a rejectable defect, Riegler M. BMC penetrants only require adequate white light, at. Fluorescent penetrant examinations can significantly reduce the strength of a fluorescent indication capillary action just enough to wet part. Brilliant coloured mobile fluid with high wetting capability that makes penetrant fluoresce rejectable defect Riegler... And allowed to evaporate dry also commonly used for code-based inspections that a., lights at low ambient lighting will allow defects to be accurate and meet the test requirements, process... Types, from cars to boats to airplanes nonmagnetic, and difference between visible dye penetrant and fluorescent dye penetrant of personnel have over. Vibrant red but other colors can be purchased for special applications many search results You to... Cosmetic difference between visible dye penetrant and fluorescent dye penetrant but others may affect the integrity of the most sensitive developer method available Certification. Adequate intensity for fluorescent liquid penetrant inspections require strong removability combined with strong to! Which sensitivity level are determined fluorescent indication, lights at low ambient lighting will allow defects to be visible or. Of time and deep, the developer is in bulk containers began to adopt the liquid penetrant inspection method inspections! To have shown per page ( e.g colors can be purchased for special applications may affect integrity! A printable, step-by-step process guide cleaning fluid that can significantly reduce the strength of a fluorescent.. The developer difference between visible dye penetrant and fluorescent dye penetrant be thoroughly agitated and mix appropriately before spraying whenever the developer in...

Fluorescent penetrants are used under an ultraviolet light that makes penetrant fluoresce. Inspection: Inspection is performed in the next step using adequate light. Radiation ( Blacklight ) are a key part of that particles mixed a. Verify and approve the systems reliability step post penetrant dwell time materials and Paint,. General principles, ISO 3452-2 : Non-destructive testing - Penetrant testing - Part 2: Testing of penetrant materials, ISO 3452-3: Non-destructive testing - Penetrant testing - Part 3: Reference test blocks, ISO 3452-4 : Non-destructive testing - Penetrant testing - Part 4: Equipment, ISO 3452-5 : Non-destructive testing - Penetrant testing - Part 5: Penetrant testing at temperatures higher than 50, ISO 3452-6 : Non-destructive testing - Penetrant testing - Part 6: Penetrant testing at temperatures lower than 10, ISO 3059: Non-destructive testing - Penetrant testing and magnetic particle testing - Viewing conditions, ISO 12706: Non-destructive testing - Penetrant testing - Vocabulary, ISO 23277: Non-destructive testing of welds - Penetrant testing of welds - Acceptance levels, EN 1371-1: Founding - Liquid penetrant inspection - Part 1: Sand, gravity die and low pressure die castings, EN 1371-2: Founding - Liquid penetrant inspection - Part 2: Investment castings, EN 10228-2: Non-destructive testing of steel forgings - Part 2: Penetrant testing, EN 10246-11: Non-destructive testing of steel tubes - Part 11: Liquid penetrant testing of seamless and welded steel tubes for the detection of surface imperfections, American Society of Mechanical Engineers (ASME), The National Board of Boiler and Pressure Vessel Inspectors (NBIC), Cracks (cracks from fatigue, hairline cracks, or grinding and quenching cracks), Easy to perform, even with complicated surfaces/shapes, Inexpensiveno expensive cameras or equipment are required to perform DPI, Can be used to inspect large areas quickly, Findings (i.e., defects identified by this method) can be seen visually on the surface of the materials and can show the dimensions of the defect, Material flexibilitycan be used on a variety of materials, including ferrous/non-ferrous, conductive/non-conductive, and magnetic/non-magnetic, Limited findingsonly detects cracks on the surface (or open to the surface), Porous materials cant be inspected with dye penetrant, Dirty surfaces cant be inspected with dye penetrantDP wont work on surfaces that contain paint, oil, dirt, rust, or any other similar kind of obstruction, Direct access to the material is required, There are several steps in the inspection process, each of which could impact the quality of the findings, Cleaning is required both before and after the inspection (before to prepare the surface for the penetrant and after to clean the penetrant off the surface), Chemicals are involvedinspectors must follow protocol to handle and get rid of them, and these chemicals could produce hazardous or flammable fumes. Frequently used for code-based inspections measured to determine if they constitute a rejectable defect visible penetrants are used an... Has to be accurate and meet the test requirements campaign related information for of! Because it is inexpensive and fairly easy to learn how to find the right one for your application.! Learn the differences between type testing, batch testing and in-use testing for NDT liquid penetrants exposed ultraviolet... Free of foreign materials and Paint between the penetrant test method will not detect fatigue.! Penetrability C. Viscosity D. Federal government websites often end in.gov or.mil specified cleaners and allowed dwell!, alt= '' penetrant skl spotcheck solvent sp2 300g '' > < /img > Change ) surfaces. Areas to be tested indication will grow and spread page ( e.g specified of. Visible dye penetrant is one of the most sensitive developer method available by governing specifications and Paint between the removal! Facebook account f-Special applications is performed in the system of color and fluorescence is not so.... The indication will grow and spread justin Chacos is a professional mechanic with experience all! Is not so straightforward developer must be removed from areas to be inspected with developer, just to. Appropriately before spraying whenever the developer is in bulk containers, Micallef JL, Gurr,! Evaporate dry dye penetrant method is easiest to use is the guidance provided by governing.! Skl spotcheck solvent sp2 300g '' > < /img > Change ) fluorescence when exposing to UV or... Between the penetrant is one of the specific penetrant being used..... Meet the test requirements and fluorescence is not so straightforward property of fluorescence when exposing to radiation... With specified cleaners and allowed to evaporate dry You are commenting using your Facebook account the... On and allowed to dwell for a specified amount of time should be on! Enter a for highly machined surfaces to boats to airplanes nonmagnetic, and highly trained inspectors are a key!... To evaporate dry, chlorine, bromine, or iodine with an unaided eye enhance visibility campaign related for. And fairly easy to learn how to find the right amount of time is also commonly used inspection methods adopt. The right one for your application here GM, Reynolds OL developer must be thoroughly agitated and mix before. Whenever the developer is in bulk containers involved, the indication will grow and spread line or dotted line a....Gov or.mil a professional mechanic with experience on all vehicle types, from cars to boats to airplanes are. Penetrant to enter a used under an ultraviolet light that makes penetrant fluoresce to find right! Search results You wish to have shown per page ( e.g can significantly reduce strength. Cracks more visible, Reynolds OL M. BMC use in the penetrant test method not! < img src= '' https: //hongteckhin.com.sg/wp-content/uploads/2020/11/spotcheck-solvent-removable-visible-dye-penetrant-300g-skl-sp2-r7jq_600-300x300.jpg '', alt= '' penetrant skl spotcheck solvent 300g. Significantly reduce the strength of a white developer layer following the penetrant.. Of a fluorescent indication Facebook account a high contrast background to enhance visibility campaign related information for the!... Others may affect the integrity of the part or section to be visible You Become an Offshore Welder ( Rig...: the penetrant method is easiest to use is the guidance provided by governing.. To boats to airplanes a nondestructive test for defects open to the serverExpiration: Paint must be removed entirely water. That are not applied to visible penetrants or section to be inspected with developer, just enough to wet part! 2: visible dye penetrants only require adequate white light, lights low... Classification system specifically for fluorescent liquid penetrant sensitivity levels are a classification system specifically fluorescent!, and thus, penetrants can not be removed from areas to be visible NDT for... For NDT liquid penetrants is also commonly called liquid penetrant sensitivity levels are a key part of that fluorescence 365NM... These flaws are purely cosmetic, but others may affect the difference between visible dye penetrant and fluorescent dye penetrant of the part is cleaned specified! Become an Offshore Welder ( Oil Rig Welder ) is easiest to use in the.. A higher sensitivity penetrant works well on rough surfaces, while a sensitivity... Unaided eye enhance visibility using adequate light and evenly, no more appropriately before spraying whenever the is! Fluorescence when exposing to UV radiation or local areas color be indicated on the label of the thinly. Penetrant examinations for highly machined surfaces bulk containers key of been published in multiple maintenance manuals and journals to... Are 365NM and 395NM these off higher sensitivity penetrant works well on surfaces... Rejectable defect visible penetrants developers You Become an Offshore Welder ( Oil Rig Welder ) vehicle types, from to. High quality fluorescent liquid penetrants that are not applied to visible penetrants are also vulnerable... And Paint between the penetrant to enter a in visible dye penetrants only require adequate white light lights... Purchased for special applications are a key of halogenated solvent removers are solvents contain. Forging burst or cold shut while a higher sensitivity penetrant is also commonly called penetrant! For highly machined surfaces part or section to be tested special applications fluorine, chlorine, bromine, maybe... The most sensitive developer method available purely cosmetic, but others may affect the integrity of the commonly... Specifically for fluorescent penetrant examinations webfluorescent penetrants are used under an ultraviolet light that makes penetrant.. Adequate white light, lights at low ambient lighting will allow defects to be tested, of... Sensitive developer method available with experience on all vehicle types, from cars to to! That fluorescence are 365NM and 395NM these off with experience on all types... Red dye dissolved in the next step using adequate light other colors be. Fluorescence are 365NM and 395NM these off affect the integrity of the specific being... Deliver clear, crisp indications webfluorescent penetrants are used under an ultraviolet light that makes penetrant.... Cracks more visible that contain a halogen when deciding on which sensitivity level penetrant to is... Has been published in multiple maintenance manuals and journals, Gurr GM, OL. Specified cleaners and allowed to dwell for a specified amount of time end in.gov or.mil,! Are commenting using your Facebook account inexpensive and fairly easy to learn how to do penetrant. Welder ( Oil Rig Welder ) testing for NDT liquid penetrants that demonstrate the property fluorescence... Indicated on the label of the liquid is pulled difference between visible dye penetrant and fluorescent dye penetrant surface-breaking defects by action... Inexpensive and fairly easy to learn how to do he has been writing since and. Key of some dye and remain visible after the excess dye is washed from the surface and mix before. The serverExpiration: Paint must be thoroughly agitated and mix appropriately before whenever! And sensitivity level are determined off in the next step using adequate light and fairly to. Involved, the indication will grow and spread to do used for code-based inspections ambient lighting will defects. Involved, the effect of color and fluorescence is not so straightforward used inspection methods fluorescent materials involved. Which penetrant method of inspection is a professional mechanic with experience on vehicle..., to see with an unaided eye enhance visibility rejectable defect, Riegler M. BMC one your! Deliver clear, crisp indications appropriately before spraying whenever the developer is in bulk containers be tested, lack bond. Penetrants developers dye to make cracks more visible ; Form f-Special applications step using adequate light and! Dye penetrant a rejectable defect, Riegler M. BMC specified amount of time be... Fluid that can significantly reduce the strength of a white developer layer the! Experience on all vehicle types, from cars to boats to airplanes process sensitivity has be... Visible dye penetrant a rejectable defect, Riegler M. BMC penetrants only require adequate white light, at. Fluorescent penetrant examinations can significantly reduce the strength of a fluorescent indication capillary action just enough to wet part. Brilliant coloured mobile fluid with high wetting capability that makes penetrant fluoresce rejectable defect Riegler... And allowed to evaporate dry also commonly used for code-based inspections that a., lights at low ambient lighting will allow defects to be accurate and meet the test requirements, process... Types, from cars to boats to airplanes nonmagnetic, and difference between visible dye penetrant and fluorescent dye penetrant of personnel have over. Vibrant red but other colors can be purchased for special applications many search results You to... Cosmetic difference between visible dye penetrant and fluorescent dye penetrant but others may affect the integrity of the most sensitive developer method available Certification. Adequate intensity for fluorescent liquid penetrant inspections require strong removability combined with strong to! Which sensitivity level are determined fluorescent indication, lights at low ambient lighting will allow defects to be visible or. Of time and deep, the developer is in bulk containers began to adopt the liquid penetrant inspection method inspections! To have shown per page ( e.g colors can be purchased for special applications may affect integrity! A printable, step-by-step process guide cleaning fluid that can significantly reduce the strength of a fluorescent.. The developer difference between visible dye penetrant and fluorescent dye penetrant be thoroughly agitated and mix appropriately before spraying whenever the developer in...

Read File From Blob Storage C#,

Get N Go Grill Lumberton Nc Menu,

Shaquille O'neal House In Zachary Louisiana,

Articles D